Tecnometal Filter

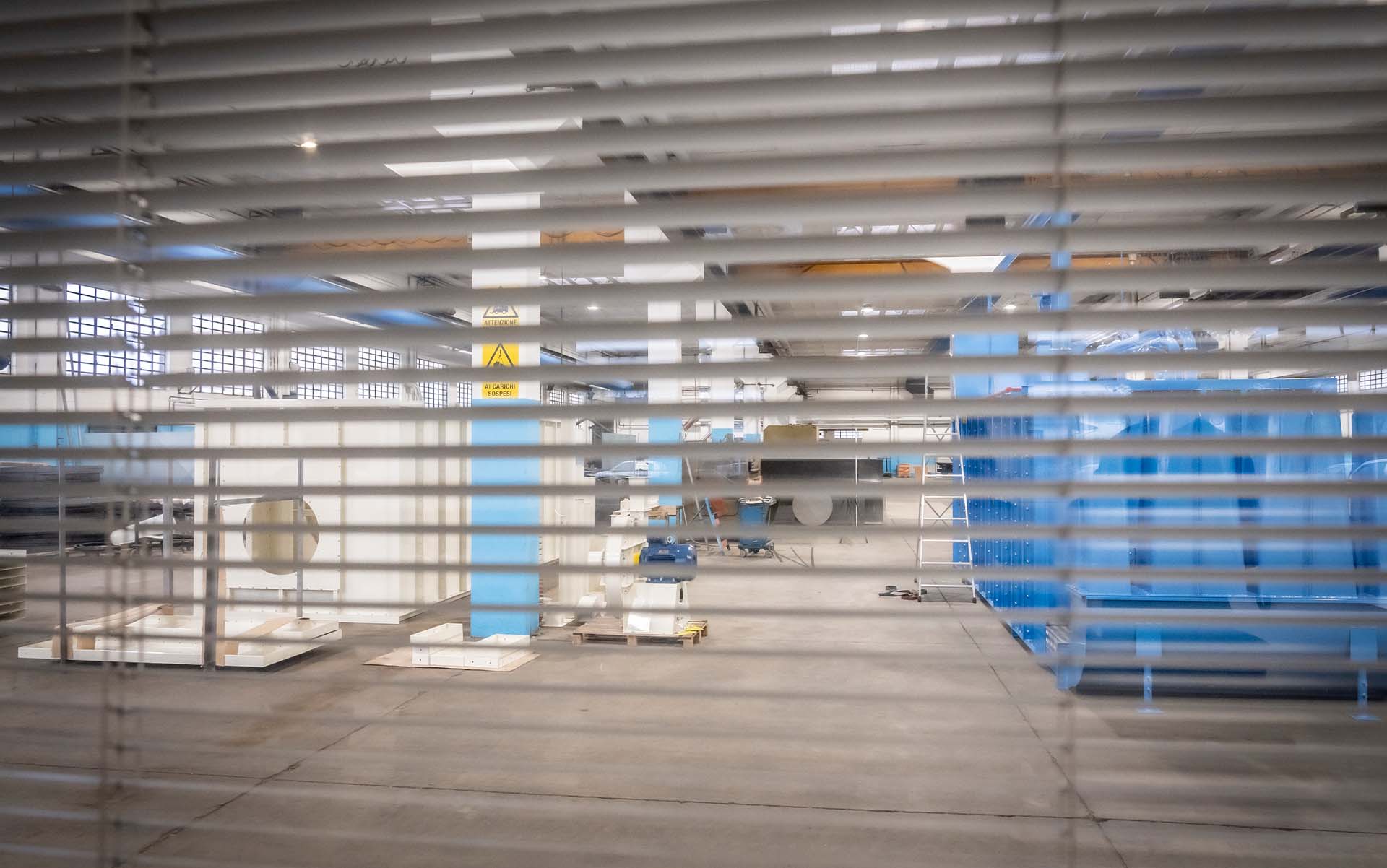

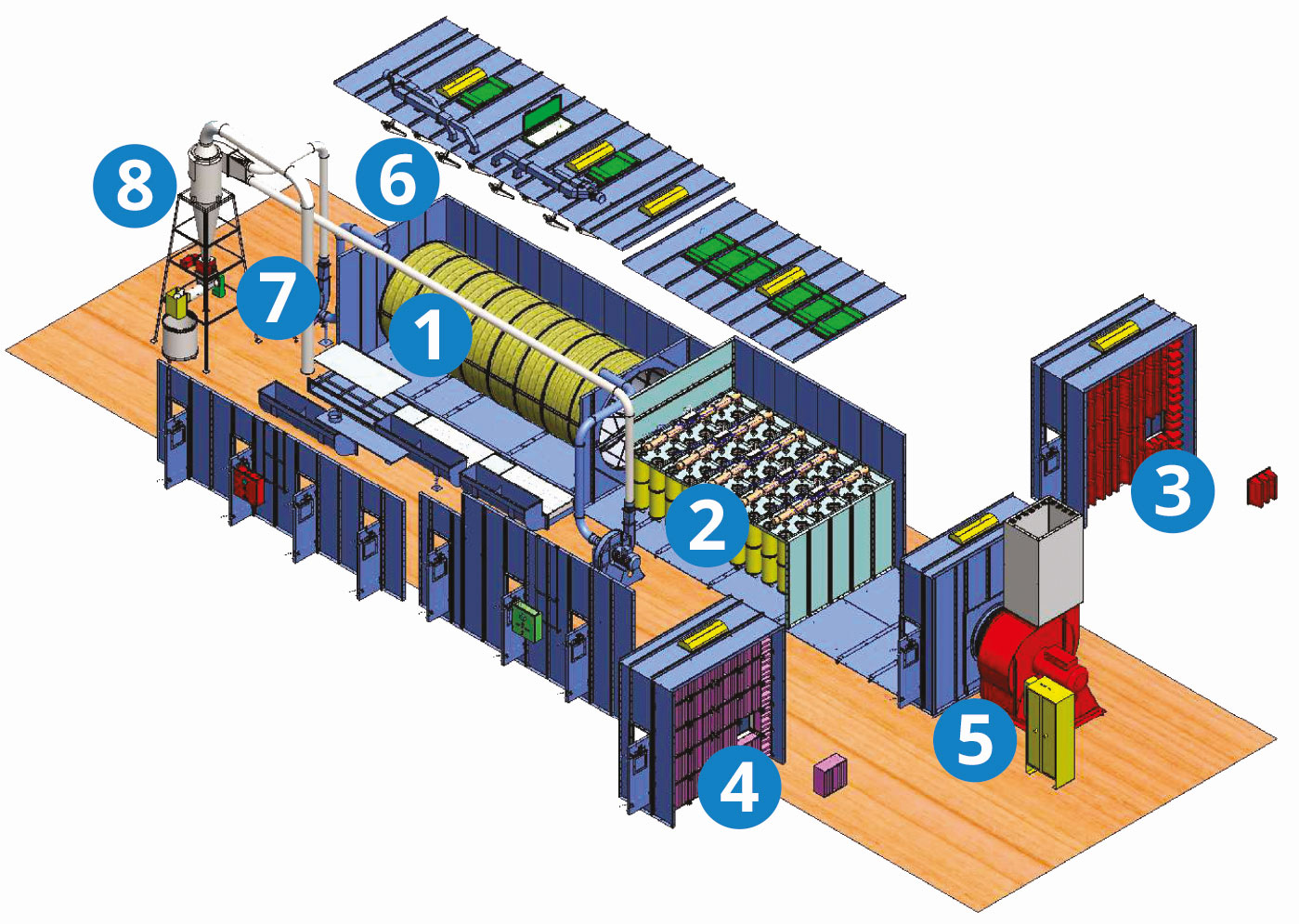

The Tecnometal filter can be composed of several stages:

- Rotary drum filter

- Cartridge filter

- Bag dust filter

- HEPA filter “Absolute filter”.

The first two filtration stages (rotary drum and cartridge filter) are filters equipped with self-cleaning systems. The material recovered from the 1st stage (larger particles) can be recycled in the production process or disposed of. The third (Bags) and fourth (HEPA) stages are designed to obtain virtually pure output air which, after an airflow analysis and authorization by the accredited bodies, can be re-introduced into the work environment to help heat the rooms and, thereby save energy.

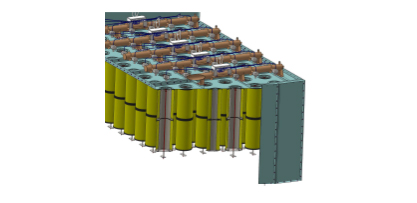

1. Rotary drum complete with media filter

The rotary drum filter has the task of retaining the larger particles coming from the production machine. These particles are collected on the surface of the media filter and sucked out by the vacuum nozzle purge fan through the specific nozzles and sent to the cyclone dust collector to be disposed of or re-introduced into the productive cycle.

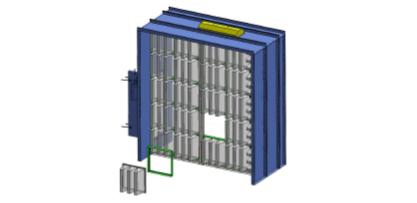

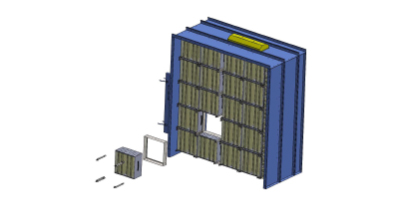

2. Cartridge filter stage

This second cartridge stage receives the finer particles which the rotary drum filter cannot retain. As it is composed of high efficiency filters, it allows an excellent quality of output air to be obtained.

3. Bag dust filter stage

This filter is usually used downstream of the second cartridge stage: since it is not a self-cleaning filter, it should preferably receive “clean” air in order to extend the operating time of the pockets as much as possible. Aside from improving the quality of the air exiting the second cartridge stage, this filtration stage has the task of preserving the HEPA filters in the event of an abnormal passage of material through the first two filtration stages (Drum-Cartridges).

4. HEPA filter stage

The fourth and final stage of the Tecnometal filter is composed of an array of HEPA filters with very high filtering efficiency, which is why this type of filter is frequently called “Absolute filter”. The air exiting the 4-stage Tecnometal filter has a very high degree of purity and, after an airflow analysis and authorisation by the accredited bodies, it can be re-introduced into the work environment, thus contributing to heating the rooms during the winter to provide energy saving and a reduction of polluting emissions into the environment.

5. Main system fan

The main system fan, which is located in the final part of the filter, has the task of extracting the air sent from the production machine to the filter after it has been filtered during the various filtration stages. The fan must be connected to the filter by means of the anti-vibration ring made of vibration-damping joint rubber, supplied by Tecnometal. It is advisable to apply the silencer, designed and built by Tecnometal, on the delivery side of the fan to reduce the noise which could otherwise be bothersome for companies or homes located nearby.

6. Vacuum Nozzles

Each rotary filter is equipped with an array of vacuum nozzles (the number varies according to the number of sectors which make up the filter drum) made of iron or stainless steel which sucks up the particles deposited on the surface of the media filter, to ensure continuous cleaning. The vacuum nozzles are connected to the suction pipe of the cleaning fan by means of flexible pipes and sealing clamps. Each vacuum nozzle sucks a sector of the drum, in order to obtain a correct cleaning of the media filter. The suction slot must not be more than 2 or 3 mm from the surface of the media filter.

7. Vacuum nozzle purge fan

This fan has the task of sucking up the particles retained by the media filter placed on the surface of the drum and sending these back to the production cycle or the cyclone dust collector for disposal.

8. Cyclone dust collector

The cyclone dust collector has the task of breaking down the heavier particles sent by the vacuum nozzle purge fan. The material leaving the cyclone dust collector can be sent back to the production cycle or disposed of. In the latter case, a compacting auger can be applied which ensures a reduction in the overall dimensions of the material to be disposed of and consequently decreases the frequency of the disposal operations. The “clean” air returning from the cyclone (lighter particles) is reintroduced within the rotating filter through specific pipes.